How does Tyvek® work?

Tyvek® is available in both a hard structure, used for HomeWrap envelopes and medical packaging applications, and a soft structure, fabric-like finish used for protective apparel and consumer applications. Discover how the science behind Tyvek® allows for superior performance across a range of applications.

Water-repellent

When the fibers in Tyvek® are spun and bonded under high heat and pressure, Tyvek® acts as a thermoplastic—returning to a high density, semi-solid state that prevents liquids from breaking the surface.

Breathability

Because no binders are used to hold Tyvek® together, tiny perforations remain in which allow water vapor to permeate the material while preventing water and other liquids from entering, making Tyvek® highly breathable.

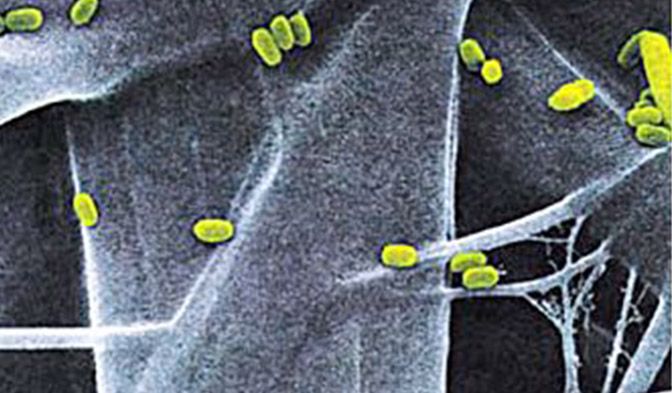

Barrier protection

Tyvek® is made up of continuous fibers that provide inherent microbial penetration resistance—preventing hazardous materials including asbestos, mold, fiberglass and lead from passing through the material.

Tensile strength

The nonwoven fibers of Tyvek® are randomly laid and compressed to provide superior tear and puncture resistance for long-lasting, durable protection.

Recyclability

Not only does Tyvek® bring unique performance benefits to a variety of applications, it’s also 100% recyclable—giving products made with Tyvek® a second life in products such as park benches and playground equipment.

Printability

Like paper, most traditional and digital printing techniques, including UV inkjet, latex and letterpress printing processes can be used on Tyvek®.